Milling machines are versatile.

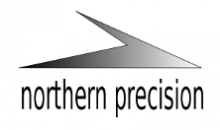

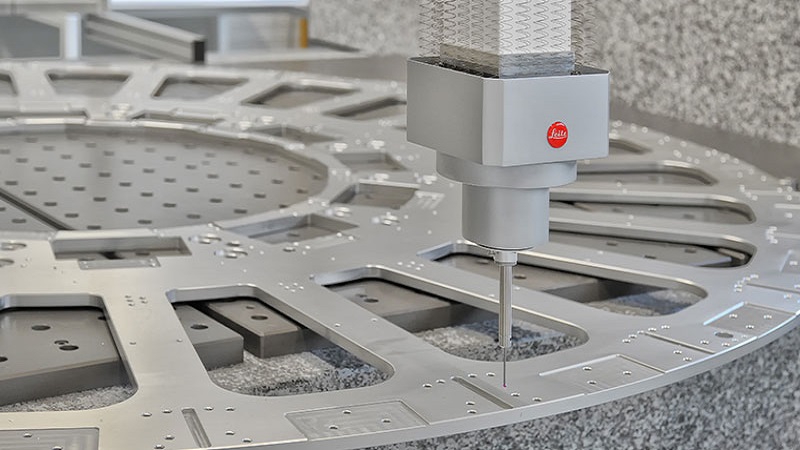

They can machine simple two-dimensional toolpaths or complex three-dimensional ones that result in extreme geometries. They can produce simple parts or highly complex ones at rapid rates. These high tolerance machined parts find their way into machines manufactured for industries like aerospace, medical, and electronic.

These machines repeat. This capability allows the manufacture of parts that are consistently within a specific tolerance range. This ability assures the parts are interchangeable and conform to the customers specifications. This repetitive ability assures that the parts manufactured are what the customer desires.

These machines allow for a mixture of high or low volume production runs. With modern part fixturing the machines can be left to produce the same part for days or quickly changed hourly to produce short volume production runs.

Milling machines produce precision parts and rapid rates. This volume of production allows the creation of the products that we use in the modern world at affordable prices.